This post addresses two problems – 1. Poverty and 2. Fashion Sustainability

1. Poverty

Philadelphia has the highest poverty level of any major city in America, upwards of 25 percent. In nearby communities such as Camden, Trenton, Darby, and Chester, the rates are higher and largely unchanged since the 1960s. Despite billions of dollars, intergenerational poverty persists.

…poverty robs individuals of opportunity many of us take for granted. No one wants to live in poverty. In fact, the people we work with are some of the most resilient I know. Understand how public policy impacts education, workforce development, housing, employment, and wellness. Understand that race and gender are significant issues, uncomfortable as that may be. Understand the perpetual crisis caused by poverty makes it difficult to attend school, hold a job, and live a productive life. Our goal should be to help individuals move permanently out of the crisis they experience.

The above quotes are from Dave Griffith’s article, Christmas wish: Reduce poverty with education, jobs, volunteerism, and advocacy, published in the Philadelphia Inquirer,

2. Fashion Sustainability

The fashion industry is notorious for being the second most polluting on Earth, next to oil and gas. Fast fashion brands have made clothes cheaper, trendier, and more accessible than ever, but this comes at the high cost of diminished resources, dangerous production conditions, chemical exposure, energy spent on transportation, and GHG emissions when these items are thrown in landfill.

Other reports have revealed the damage caused by polyester fabrics when washed. Tiny plastic microfibres become dislodged in the washing machine and flushed into waterways, where they are ingested by marine wildlife and enter the food chain. It brings a whole new disturbing meaning to the idea of “eating one’s shirt.”

new report from the Ellen MacArthur Foundation outlines

…I made my first mistake: I bought a very expensive sewing machine with a multitude of gadgets and dials. (Little did I know then that I would never be called upon to use all those fancy accessories. A simple machine with just the basic stitches — straight, stretch, and zigzag — and a buttonhole-maker would have served my purposes well. and saved me a big chunk of money.)

How to Profit From a Home Sewing Business | MOTHER EARTH NEWS

Possible solution that might help to solve both poverty and fashion sustainability problems

Scaled-down technology

Small Is Beautiful is Oxford-trained economist E. F. Schumacher’s classic call for the end of excessive consumption. Schumacher inspired such movements as “Buy Locally” and “Fair Trade,” while voicing strong opposition to “casino capitalism” and wasteful corporate behemoths. Named one of the Times Literary Supplement’s 100 Most Influential Books Since World War II, Small Is Beautiful presents eminently logical arguments for building our economies around the needs of communities, not corporations.

Overview from the Barnes and Noble website.

More about Fritz Schumacher and his ideas can be learned from this video, Small is beautiful impressions of Fritz Schumacher

Excerpts from the book, Small is Beautiful:

Although Fritz Schumacher never mentions the fashion industry, in his book, Small is Beautiful, he points out that industrial production needs to be

scaled down to the village level. A “modern” workplace…can be really productive only within a modern environment, and for this reason alone is unlikely to fit into a “district” consisting of rural areas and a few small towns. page 188.

…the problem presents an enormous “intellectual” challenge. The aid-givers-rich, educated, town-based–know how to do a few big things in their own way…. On the whole they do not know; but there are many experienced people who do know…. page 208

…the necessary knowledge, by and large, exists;…. The best aid to give is intellectual aid, a gift of useful knowledge. page 208

This, then, should become the ever-increasing preoccupation of aid programs–to make men self-reliant and independent by the generous supply of the appropriate intellectual gifts, gifts of relevant knowledge on the methods of self-help. …if the goods are rightly chosen, those who need them can probably pay for them. page 209

Summary – Philadelphia’s potential

Philadelphia, PA 19118 Pop-up shops, similar to Ten Thousand Villages, that showcase work from Third World Counties, might be a way to start getting products known that are made here in Philadelphia.

When I worked as a patternmaker/grader/fit model in the factories in Philadelphia I saw how talented the women who did the production sewing in the factories were. Hard working, they were buying their homes, sending their children to school, getting ahead. Unfortunately, when the factories closed, there was no way for them to learn the design room skills that would have enabled them to start small businesses in their homes.

If those skills made available to residents in North and West Philadelphia, those communities might eventually be able to supply many of the cities throughout the world with high-end clothing. The people there, as is true everywhere, have the potential to organize and work together. Production would move from house-to-house. Some would design, others draft, cut, market, advertise. There would be no need of any factory building. Only minimal drafting and sewing equipment would be needed. When the factories went off-shore the women bought the machines they had used in the factories. Many of those sewing machines are still in their basements, some being used. Feather weight sewing machines could also be used.

Giving the communities’ youth leaders scholarships, might be the way to start. The leaders would then train their youth groups. Fashion shows for the different youth groups would encourage competition. Before long some industry should begin to start up.

Educational costs would be low. Grants would pay the basic class costs. Classes could be taught almost anywhere there is space for long tables. Long tables are needed as most of the class work would be pattern drafting. No sewing machines are needed. The instructor would demonstrate the sewing exercises in the classroom on a small portable sewing machine she brought from home. The students would do the assigned sewing exercises on their machines at home. In their classes the youth leaders would be making clothing from donated fabric for themselves, learning how to fit themselves and the others in the classroom. (Ask for donated fabric, and it will come in. Many women who sew have fabric they would like to donate.)

In the process the leaders and their clubs are making high-end clothing that raises self-esteem and enables better jobs. Students are also learning low-engineering skills that may encourage young girls to study engineering.

In time – no more than a couple of years, pop-up shops, similar to Ten Thousand Villages that showcase work from Third World Counties, might be a way to start getting their products known here in Philadelphia, the first step to selling on the world market.

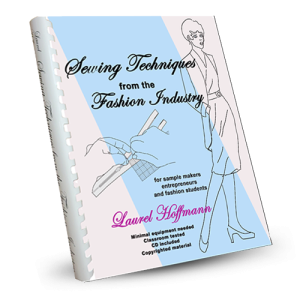

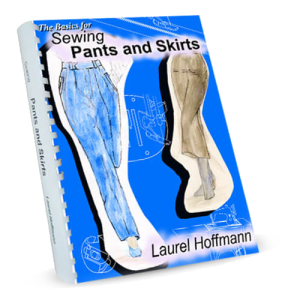

Contemporary Fashion Education’s books support the fashion technology program that was developed in continuing professional education classes at two leading Philadelphia Universities over a period of 18 years. The typical student had a master’s degree. Most wished to sew for themselves. Some were sent in from the industry for training. Those who wished to enter the industry were successful, working as patternmakers for well-known firms, including Federated and Jones of New York. The program can be taught in two years or less.

http://localhost/cfashion/

https://twitter.com/LaurelHoffmann1

https://www.facebook.com/CFashionEdu

https://www.linkedin.com/in/laurelhoffmann/

https://www.ravelry.com/projects/LaurelHoffmann

https://www.thumbtack.com/pa/philadelphia/drawing-lessons/fashion-drafting-sewing-books-classes

5 Comments. Leave new

In summary: The goal is to enable North and West Philadelphia to be able to develop their ideas into world-class products that can be sold on the global market. Laurel

Thank you! Laurel

Fascinating concept!

Thanks, Alice!

Thank you! I try to write once a week, but sometimes I’m really busy and it takes longer.