Knowing industrial pattern making and sewing enables one to make clothing that may otherwise be unobtainable.

Years ago, having retired from production pattern making to raise my children, I decided that the pattern making and sewing methods used in designing departments should be available for lay people to learn and use.

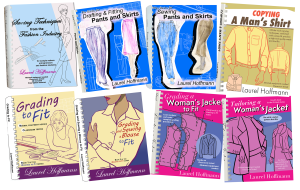

I thought it would be one book and take about a year to write what I knew. It was just as well that I didn’t know what I was getting into. The book turned out to be eight books that took 30 years to write.

Contrary to popular opinion, industrial sewing can be done on very basic machinery, it can even be done on a treadle. It was the invention of the treadle sewing machine that made it possible to move clothing manufacturing into the factories.

One can date when the treadle sewing machine was invented as it was then that anti-bellum gowns became fashionable, gowns that involved yards and yards of sewn fabric, advertising the husband’s affluence.

When I entered the industry I was stunned to learn how differently the industry sewed

The methods used in industry were so much easier and much more reliable. As I learned pattern making and grading, needed for my job, I made sure to also learn the sample making procedures. I wanted to be able to sew professional clothing or my family and myself like that made in the designing departments. I asked the sample makers how they sewed. Although not allowed to sew on the machines while on the clock (I was management. Only union was allowed to sew on the machines), I practiced at lunch and at home.

Once retired to raise my children, I began sewing at home. I bought home-sewing patterns to speed the drafting, using the same drafting procedures I had learned in industry to set up the purchased patterns.

Before I had gone into the industry I had made clothing using home-sewing instructions. But only about one in three garments were ever really successful. No wonder. The instructions were awful! I decided to rewrite them. I figured it would take me about a year.

I never thought the one book I had decided to write would turn into books. That I would start a publishing company, would teach for years in college while developing a graduate level program, or have my own online school.

Once I moved over from the college fashion-degree program to teaching in Continuing Professional Education I was free to write and teach, using my own methods. My adult students asked for what they needed, enabling me to learn what was needed in the books, and how the books needed to be written.

Maybe it was just as well I didn’t know what I was getting into. I wrote for 30 years. One book turned into six, then seven, now eight. My son, Andrew, a graphic designer/production editor, helped me with the covers and with setting up the paragraph styles. I wrote everyday until all eight books were finished in March of 2022.

What kept me going? My students’ enthusiasm.

My goal was to produce heavily diagrammed and illustrated picture books that would take a layperson step-by-step through the process of drafting and sewing that would enable her to correct her patterns to her personal fit, then use the easier industrial sample making procedures to produce professional garments; clothing that would not beg the question, Did you make it?

I hoped to eliminate all writing – I wanted to have just pictures in the book. But I found I had to add writing as my students also needed written explanation. However, the emphasis continues to be on the visual, as most people who sew learn from the graphics, reading the captions and writing only if needed to clarify the diagrams.

Here are four of the reasons this information isn’t available:

1. Most of the people who do the sewing in the industry are not college educated. Those who become sample makers (seamstresses who can sew an entire garment together using the sewing procedures that will be used to make the garment when it goes into mass-production) have risen up through the factory ranks, learning industrial procedures step-by-step until they know the whole process. They then either become foreladies, or are promoted into the designing department where they sew the sample garments using the sewing techniques that will be used when those garments are sewn on the factory floor, checking for problems as they sew the garments together. Although intelligent, because they do not have college degrees they rarely, if ever, are hired to teach in college. They also rarely have the skills or the opportunity to write down the sewing methods they have learned in industry. This is the fundamental reason the sewing books on the market present home sewing.

2. Few people, including the editors at publishing houses, know how industrial sewing done. This is unfortunate as there are many people who might be able to manufacture small runs of sewn products in their home and sell them in local stores or on the net. There’s no way anyone can be truly successful with sewn product manufacturing if they don’t have industrial skills. Home sewing methods just take too long. They also, too often, produce less than professional results.

3. Because pattern making has a symbiotic relationship with sewing, pattern making skills have to be included with the sewing instructions. Pattern making requires good fitting skills. In other words, books that give the information that is needed are difficult to write and illustrate. As I have found out, it takes years and requires classroom testing to be sure the information is accurate and can be understood.

4. Before the computer it was impossible within a reasonable time frame to diagram and write this material so that lay people could understand it. Just one of my books would have taken a life-time to complete.

5. Home sewing books sell. Publishers prefer to publish books that have a guaranteed market.

Here are some of the problems caused by lack of access to this information:

1. Industry doesn’t know where to find the trained workers it needs.

2. Many people who are highly proficient at home sewing might like jobs in the industry, but unfortunately they need to be retrained if they are to be hired. Home sewing procedures can NOT be used in the industry.

3. Because factory workers are specialized, few are cross-trained. When the factory system left the USA, most of the factory seamstresses didn’t have the pattern making skills they needed that would have enabled them to start manufacturing small lots in their homes.

4. Industrial sewing and pattern making is low-level engineering. Learning industrial sewing would be an excellent preparation for young girls to realize a future in engineering. Unfortunately such programs are almost unavailable.

5. Because home sewing is taught in many, if not most fashion training programs, students are often unable to get jobs in the fashion industry.

Why learn industrial pattern making and sewing?

Because knowing how to produce professional garments is fun.

LaurelHoffmann-YouTube

https://laurelhoffmann.com/

https://www.facebook.com/CFashionEdu

https://www.linkedin.com/in/laurelhoffmann/

https://www.instagram.com/laurelhoffmann4015/

RSS Feed: https://laurelhoffmann.com/blog/

https://www.ravelry.com/projects/LaurelHoffmann

https://www.yelp.com/biz/laurel-hoffmann-oreland

https://www.thumbtack.com/pa/philadelphia/drawing-lessons/fashion-drafting-sewing-books-classes